Penpal

Grand Master

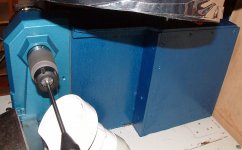

My layout for my requirements Yesterday I made a thick heavy shorter Pen Rest welded on to a 1 inch stem cause the increased size of the tool rest and my favourite angle rest, gazing during the week at the fine dust removal unit it was a metre above the lathe so I fitted a 10 inch tubing down to the lathe figuring the dust collection needs to be near the source it is designed for duct extraction in line really moves a lot of air. Bought a ten litre indestuctable brickies bucket fitted to give strength above the lathe this taped to a cross arm with aluminium tape the cross arm to the shelves is Ebony.

Beneath the bench is a Thien Filter between the Lathe and an industrial vacuum cleaner it roars (overkill YES) note the Vermec Precision Collet Chuck, the Mandrel Saver from the USA. The VFD

(Variable Frequency Drive) converts AC 240 Volts to enable the new 1.1 KW Motor to be used as an inverted control the variable speed is acheived with the variable pot built into the face. The unit is switched on by the green button speed set when finished press the red off button. I programmed the unit by phone hook up to the dealers Control Techniques in Sydney took 15 mins it is a really full on controller but all I wanted was simply on off speed control. The motor as well is over the top but the controller gives soft start no spike currents and runs about 2 amps more grunt than Jessie the Elephant.

Very careful about belt covering to and from the motor horror stories abound using uncovered belting at speed.

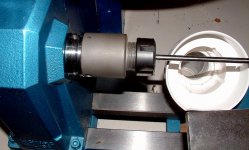

Vermec the brother of Vicmarc sold me their precision Collet holder and fifteen collets when running dead smooth. The mandrel saver is from the US. Adjacent to the lathe is a press mounted at eye height on a separate table with a variable speed controlled small buff a lab stirrer in a previous life 3 inch buff.

I chucked a couple of pieces of ply behind the lathe need to put things back on the shelves this week.

Still more to setting up around the lathe there is another industrial vac alongside the lathe for the large Mill-Drill adjacent.

Kind regards Peter

Beneath the bench is a Thien Filter between the Lathe and an industrial vacuum cleaner it roars (overkill YES) note the Vermec Precision Collet Chuck, the Mandrel Saver from the USA. The VFD

(Variable Frequency Drive) converts AC 240 Volts to enable the new 1.1 KW Motor to be used as an inverted control the variable speed is acheived with the variable pot built into the face. The unit is switched on by the green button speed set when finished press the red off button. I programmed the unit by phone hook up to the dealers Control Techniques in Sydney took 15 mins it is a really full on controller but all I wanted was simply on off speed control. The motor as well is over the top but the controller gives soft start no spike currents and runs about 2 amps more grunt than Jessie the Elephant.

Very careful about belt covering to and from the motor horror stories abound using uncovered belting at speed.

Vermec the brother of Vicmarc sold me their precision Collet holder and fifteen collets when running dead smooth. The mandrel saver is from the US. Adjacent to the lathe is a press mounted at eye height on a separate table with a variable speed controlled small buff a lab stirrer in a previous life 3 inch buff.

I chucked a couple of pieces of ply behind the lathe need to put things back on the shelves this week.

Still more to setting up around the lathe there is another industrial vac alongside the lathe for the large Mill-Drill adjacent.

Kind regards Peter