jackjohnsonuk

Apprentice Member

Hi all,

Need some help please on getting started with casting resin blanks and stabilising, I have a reasonable amount of spalted wood I got off my Grandad when we emptied his workshop, and need to get it in a form suitable for turning.

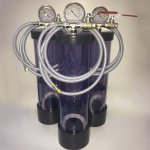

From what I've read a vacuum chamber would be what I need, and as always, I'm on a budget. I do have a vacuum already from my vacuum chuck so that's one less thing to buy. Is the below any good for a pressure pot, it seemed the most wallet friendly option:

PlusVAC 20L Vacuum Degassing Chamber & safety air release valve (LAST FEW!) UK! | eBay

Open to any hints and tips, thanks for any help and advice

Jack

Need some help please on getting started with casting resin blanks and stabilising, I have a reasonable amount of spalted wood I got off my Grandad when we emptied his workshop, and need to get it in a form suitable for turning.

From what I've read a vacuum chamber would be what I need, and as always, I'm on a budget. I do have a vacuum already from my vacuum chuck so that's one less thing to buy. Is the below any good for a pressure pot, it seemed the most wallet friendly option:

PlusVAC 20L Vacuum Degassing Chamber & safety air release valve (LAST FEW!) UK! | eBay

Open to any hints and tips, thanks for any help and advice

Jack