-

Thanks for visiting The Penturners Forum today.

There are many features and resources that currently you are unable to see or access, either because you're not yet registered, or if you're already registered, because you're not logged in.

To gain full access to the forum, please log in or register now. Registration is completely free, it only takes a few seconds, and you can join our well established community of like-minded pen makers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

martin.pearson

Full Member

These look great, thanks for sharing.

alan morrison

Fellow

NICE !!! I sure you are well pleased with them Derek

Alan

Alan

Penpal

Grand Master

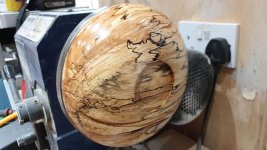

Two of a kind with variation chunky and appealing to me.

Peter.

Peter.

wm460

Grand Master

- Joined

- Mar 16, 2013

- Posts

- 23,103

- First Name

- Mark

Great looking bowls Derek.

Very nice grain patterns nicely shown off Derek.

Hello Derek

I like the bowls. I am working on one of the spalted Walnut blanks you gave me. Had to use some CA in places but should turn out OK.

I will post some pictures when finished.

Cheers

Frederick

Look forward to seeing it well worth the effort I did one a little while ago

WHCreations

Full Member

Really like that shape. I got given a piece of spalted beech that no one else would touch due to cracks. I cut it in half to make two bowls as i wasnt sure what design I liked. this would have been perfect! Great work and a beautiful finish!

Thank you, William. Bowl design is all about the wood showing it off to it's best as well as what is pleasing to the recipient. Look at shapes of pottery from years ago like the greek and roman bowls and other items this will give an idea for shapes.

WHCreations

Full Member

Thank you, William. Bowl design is all about the wood showing it off to it's best as well as what is pleasing to the recipient. Look at shapes of pottery from years ago like the greek and roman bowls and other items this will give an idea for shapes.

i never even thought of that! im on it!

WHCreations

Full Member

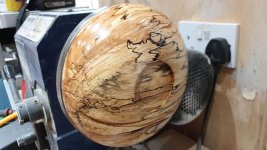

This was my spalted bowl. I have not been turning bowls for very long. I think this was my 4th or 5th. I normally use carbide but this time i decided to use my HSS. I tried my bowl gauge on the first bowl and it scared the hell out of me, so decided against them. But i prevailed and was please by how it went. It has such a smooth as silk finish too!

alan morrison

Fellow

Very attractive bowl and markings, William

Nice looking bowl William. The only thing I would change on it is try to keep the wall thickness the same from the lip down to the bottom it may mean using a tenon rather than a mortice then remove the tenon. These are things that after a while will become easier to do.

I very rarely use carbide tools even when doing hollow forms. With a bowl gouge, I feel you can get a much better finish and reduces the amount of tear out especially on softer woods. It pays to get someone to show the best way to use any of the tools for woodturning. I have 4 bowl gouges one for heavy and deeper work and the other three with different grinds.

Most of the time I will start sanding at about 240 grit that does not mean that I will not go courser

I very rarely use carbide tools even when doing hollow forms. With a bowl gouge, I feel you can get a much better finish and reduces the amount of tear out especially on softer woods. It pays to get someone to show the best way to use any of the tools for woodturning. I have 4 bowl gouges one for heavy and deeper work and the other three with different grinds.

Most of the time I will start sanding at about 240 grit that does not mean that I will not go courser

WHCreations

Full Member

I think its safe to say i bottled it haha. I agree with you about the thickness but its all learning and i will take that into account the next time i make one. My expertise aren't on the lathe but more into furniture designing/making. I just enjoy taking a few hours off that and throwing something on the lathe instead. This one was more of a "I can make it work" sort of thing as so many people had turned their nose up at it. I do love watching people turn and find it fascinating. Just loving seeing all the amazing work created by you lot at the moment!

I think its safe to say i bottled it haha. I agree with you about the thickness but its all learning and i will take that into account the next time i make one. My expertise aren't on the lathe but more into furniture designing/making. I just enjoy taking a few hours off that and throwing something on the lathe instead. This one was more of a "I can make it work" sort of thing as so many people had turned their nose up at it. I do love watching people turn and find it fascinating. Just loving seeing all the amazing work created by you lot at the moment!

I just play at turning and have so much to learn. I try to push myself a bit far sometimes