Bit of a day today where I encountered a problem with my lathe and then spent a large part of the day fixing it. One of those things where it’s such an innocuous small break, but it brought everything to a halt and I couldn’t really move on until it was addressed.

The issue I had is on my metal lathe and the photo shows the piece that broke.

Just to explain, this entire cast piece sits on top of the ways and forms the base of the tailstock, the top half of which sits directly on top of it. The front edge faces the headstock, and the main purpose of this component is to allow alignment of the tailstock. There are two grub screws that come through the each side of the upper part of the tailstock and they register against the two lugs that you can see (one of which has snapped off). So if you need the tailstock to move slightly away from you then you tighten the far side grub, and it pushes itself, and hence the upper part of the tailstock that it’s connected to, away from you . To move it towards you then you tighten the near side grub screw. Pretty simple and very effective. Until one of the lugs snaps off that is! Not only does this mean you can’t align things properly, but this is the same lug that the locking bolt, that comes through the back of the tailstock, also registers against. So basically the whole thing starts flopping about.

I spoke to Arc Euro and they do sell this part but it’s out of stock until March.

So I had to try to fix it myself and this is what I came up with:

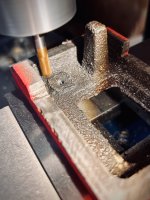

First I milled the area where the lug snapped off so it was completely flat. Here is a “before” picture on the mill:

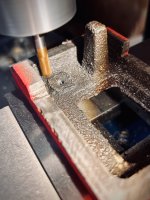

And here is it once milled:

Then I drilled and tapped the centre of the milled square area to take an M5 bolt:

The final part was to take that small aluminium rod on the left in the photo and drill, tap and shape it and then screw it onto the bolt. I spent quite some time putting it back onto the lathe and aligning things and then realised I hadn’t taken a photo of the final outcome, but suffice to say it worked pretty well and actually is better than the original.

This was one of those things which, when it happened, I was a bit miffed but once I’d started working on it I really enjoyed it. It’s very satisfying when you fix your machines. No matter how basic the fix is!

And this does highlight the difference between buying a relatively cheap Chinese import lathe like mine compared to buying a high quality British made machine with the quality and warranties they offer. As they say, you pays your money, you takes your choice…

Cheers

Ash

The issue I had is on my metal lathe and the photo shows the piece that broke.

Just to explain, this entire cast piece sits on top of the ways and forms the base of the tailstock, the top half of which sits directly on top of it. The front edge faces the headstock, and the main purpose of this component is to allow alignment of the tailstock. There are two grub screws that come through the each side of the upper part of the tailstock and they register against the two lugs that you can see (one of which has snapped off). So if you need the tailstock to move slightly away from you then you tighten the far side grub, and it pushes itself, and hence the upper part of the tailstock that it’s connected to, away from you . To move it towards you then you tighten the near side grub screw. Pretty simple and very effective. Until one of the lugs snaps off that is! Not only does this mean you can’t align things properly, but this is the same lug that the locking bolt, that comes through the back of the tailstock, also registers against. So basically the whole thing starts flopping about.

I spoke to Arc Euro and they do sell this part but it’s out of stock until March.

So I had to try to fix it myself and this is what I came up with:

First I milled the area where the lug snapped off so it was completely flat. Here is a “before” picture on the mill:

And here is it once milled:

Then I drilled and tapped the centre of the milled square area to take an M5 bolt:

The final part was to take that small aluminium rod on the left in the photo and drill, tap and shape it and then screw it onto the bolt. I spent quite some time putting it back onto the lathe and aligning things and then realised I hadn’t taken a photo of the final outcome, but suffice to say it worked pretty well and actually is better than the original.

This was one of those things which, when it happened, I was a bit miffed but once I’d started working on it I really enjoyed it. It’s very satisfying when you fix your machines. No matter how basic the fix is!

And this does highlight the difference between buying a relatively cheap Chinese import lathe like mine compared to buying a high quality British made machine with the quality and warranties they offer. As they say, you pays your money, you takes your choice…

Cheers

Ash