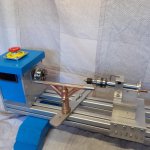

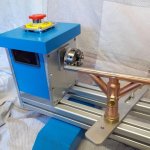

Brian Rutter

Apprentice Member

Today I started to order some pulleys and belts, my wallet had a nervous breakdown:wink:

So plan B.

Take 12 milk bottles, bake in the oven at 175 DegC for 30 minutes and press into some 2" and 2.1/2" copper pipe.

The idea is to turn the pulleys to make the lathe son I can turn the pulleys.

So I used an electric drill clamped to a piece of scaffolding plank .

You may laugh, but I am so chuffed my socks are jumping up and down. I have never turned anything before and the pulley cost nowt.

I promise I will make a proper one when my lathe is operational.

So plan B.

Take 12 milk bottles, bake in the oven at 175 DegC for 30 minutes and press into some 2" and 2.1/2" copper pipe.

The idea is to turn the pulleys to make the lathe son I can turn the pulleys.

So I used an electric drill clamped to a piece of scaffolding plank .

You may laugh, but I am so chuffed my socks are jumping up and down. I have never turned anything before and the pulley cost nowt.

I promise I will make a proper one when my lathe is operational.

just wait

just wait