Brian Rutter

Apprentice Member

Using Ohms law the motor specs you have posted doesn’t tally with that calculation Brian.

W divide by V = R

150\12 makes it 12.5 amp loading.

Every time I look at this I find contradictory, missing and confusing information. The loading figures come from one of the information sheets on ebay. I have used that calculation but did not believe it, I can run my electric oven with that.

Additionally a 12.5Amp 220AC/12VDC power pack is a serious bit of kit.

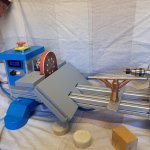

My build is based on a lathe built by "Uri Tuchman" he is a guy I follow on You Tube, well worth a look he builds some wonderful stuff.

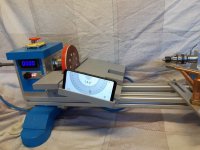

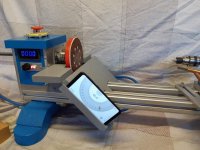

The lathe was originally powered by a treadle from an old sewing machine but he electrified it with the motor I have copied and controlled it with this

DC PWM Motor Controller Reversible 12V 24V 36V 40A Hochleistungs-Motor Drehzahlregler Schalter CCM6Ds-B: Amazon.de: Gewerbe, Industrie & Wissenschaft