Well I got home from work much earlier than expected today so got out to the workshop. In terns of work flow I'm pretty much showing my method step by step...not because I think it's the best way to do it but just because this is how I do it. This is only my 6th kitless pen.

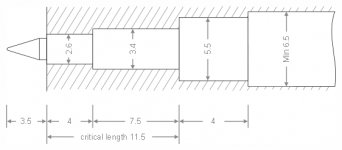

First step with the nib is a piece of blank about 5mm long on which a tenon is turned for the M9 x 0.75 thread.

Next a thin parting tool is used to clear up the back of the threads so that the nib section will screw fully into the barrel.

Then comes the drilling for the refill. Centre drilled first and then drilled 33mm deep with a 1/4 inch drill bit.

Then a 3/16 bit for another 3mm (love using imperial and metric at the same time...)

I then reverse the nib section in the collet and drill through with a 7/64 bit.

Finally for this post a test fit of the nib in the barrel with a refill in...perhaps the nib section is a tiny bit short. I'd have preferred less nib sticking out...

Sent from my SM-G900F using Tapatalk