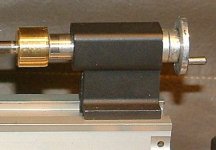

Making some kind of adjustable boring tool that fits in the tailstock may work if you need to regularly bore stuff accurately.

Another option is some kind of platform to replace the tool rest that can be accurately set up in line with the bed bars?

The problem is that at present any tool you use can be presented at an (unwanted) angle.

Another option is some kind of platform to replace the tool rest that can be accurately set up in line with the bed bars?

The problem is that at present any tool you use can be presented at an (unwanted) angle.